₹0.00

| Capacity | 700 roties per hour |

|---|---|

| Chapati diameter | Up to 8 inch |

| Chapati thickness | Adjustable from 0.9 mm to 2 mm |

| Electric consumption | 1.5 kw approx. |

| Gas consumption | 1-1.5 kg per hour approx. |

| Features | Rotipro Machine | Other Machines |

|---|---|---|

| Moisture Locking Technology | Provided – Preserve moisture of roti to provide extra soft roties

EXTRA SOFT ROTI

|

Not Provided – Absorb moisture from roti to render it dry and hard

DRY & HARD ROTI

|

| Blue Flame Burner Technology | Provided – Gives perfect puff in rotis

EXTRA PUFFED ROTI

|

Not Provided – Roti is not puffed properly

SHRINKED ROTI

|

| Reduced Pre-Heating Time | Provided – Takes Less Time To Preheat The Machine

SAVES ENERGY

|

Not Provided – Takes More Time To Pre-Heat The Machine

ENERGY LOSS

|

| Food Grade Non Stick Coating | Provided – Contamination Of The Material With Roti NOT Occurs Due To Standardised Method Used For Non Stick Coating Treatments.

FOOD GRADE

|

Not Provided – Sustained Contamination Occurs Due To Low Grade & Non Standard Coating Treatments. |

| Specialized Lubricated Bearing | Provided – Special Purpose High Temperature Lubricant Used, Which Does Not Melt In High Temperature, So It Prevents Oil Contamination With Roti

FOOD GRADE

|

Not Provided – Under High Temperature Environment Ordinary Lubricants Gradually Melts And Mix With Roti. |

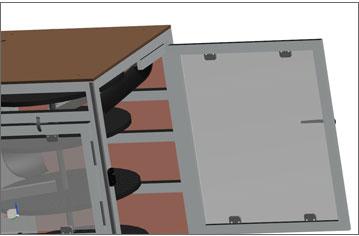

| Safe Toughened Glass Cabinet Wall | Provided – Does Not Crack In High Temperature Environment, As Well As It Saves Heat Loss During Process.

SAVES ENERGY

|

Not Provided – Ordinary Glass Cabinet Used, Which Can Crack During Operation As Well As Heat Loss Is High.

ENERGY LOSS

|

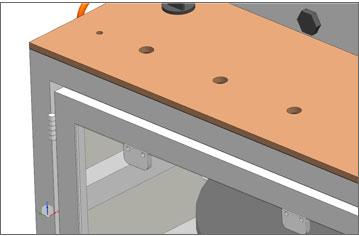

| Fire Proof Cabinet Top | Provided – Fire Hazardous Is Eliminated Due To Specialized Fire Proof Cabinet Top, As Well As It Saves Heat Loss During Process.

ENERGY LOSS

|

Not Provided – Chances Of Fire Hazardous Is More During Process As Well As Heat Loss Is High.

ENERGY LOSS

|

| High Quality Branded Gas Fittings | Provided – Considering Long Life Of The Machine & Safety Precautions We Always Use Such Gas Fittings. | Not Provided – Lower Quality Gas Fittings Are Not Safe & Poor Running Life |

| High Quality Standard Motors | Provided – Motors Are High Quality Standard Motors Branded Having Superior Quality Performance With Long Life | Not Provided – Poor Quality Motors Requires More Maintenance In High Temperature Working Environment. |

| Internationally Standard Branded Electrical Panel Accessories | Provided – We Use “Schneider Electric” Or Equivalent International Standard Branded Panel Accessories, Which Provides Machine With Long Life & Maintenance Free Operation. | Not Provided – Non Standard Panel Accessories Results High Maintenance Cost |

| Heavy Duty Steel Body | Provided – We Use 1.5 Mm Thick Stainless Steel Sheet Metal | Not Provided – In Ordinary Machine < 1 Mm Thick Sheet Metals Are Used. |